CNC Milling Machine UK: The Future of Precision Engineering

The landscape of manufacturing is continuously evolving, and one of the most significant innovations driving this change is the CNC milling machine. In the UK, the adoption of CNC (Computer Numerical Control) technology is redefining capability and efficiency in various industries. This article delves into the advantages of CNC milling machines, their applications, and why investing in these machines through platforms like roc-tech.com is crucial for businesses seeking a competitive edge.

1. Understanding CNC Milling Machines

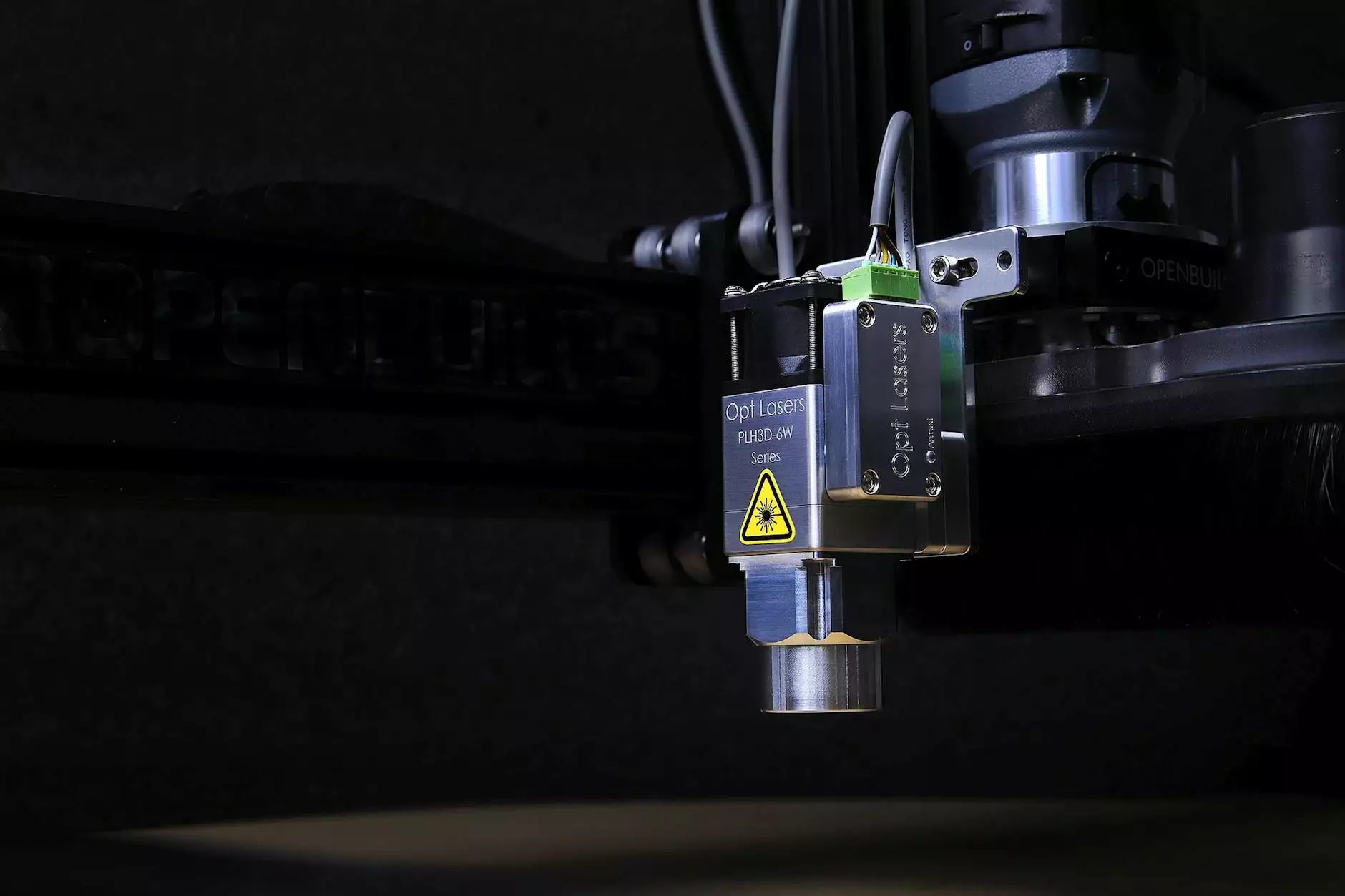

A CNC milling machine is a sophisticated tool that automates the process of cutting, drilling, and shaping materials such as metals, plastics, and composites. The precision offered by CNC technology allows for intricate designs and shapes, making it an invaluable asset in modern manufacturing.

1.1 How CNC Milling Machines Work

The operation of a CNC milling machine is both fascinating and complex. Here’s a simplified breakdown of how these machines function:

- Design Input: The process begins with creating a digital design using CAD (Computer-Aided Design) software.

- Conversion to Code: The CAD file is converted into G-code, a language that CNC machines understand.

- Machine Setup: The CNC machine is set up with the necessary tools and materials. This is where precision becomes crucial.

- Execution: The CNC machine executes the G-code commands, precisely cutting and shaping the material.

With this method, CNC milling machines can achieve tolerances as tight as 0.01 mm, making them ideal for industries where precision is paramount.

2. Advantages of CNC Milling Machines

Investing in a CNC milling machine in the UK does not merely enhance productivity; it also brings a myriad of benefits that can transform a business's operations.

2.1 Enhanced Precision and Consistency

With traditional milling methods, human error can lead to inconsistencies. However, CNC milling machines operate with high precision, ensuring that every piece produced meets strict specifications. This level of consistency is critical for industries such as aerospace and automotive, where the slightest deviation can lead to catastrophic failures.

2.2 Increased Efficiency and Productivity

CNC machines can operate continuously without fatigue, allowing for uninterrupted production runs that significantly boost efficiency. Businesses can achieve higher output without compromising on quality.

2.3 Flexibility in Production

Switching between projects is seamless with CNC milling machines. They allow manufacturers to produce small batches of customized parts without extensive re-tooling. This adaptability is critical in a market that increasingly demands tailored solutions.

2.4 Cost-Effectiveness

While the initial investment in a CNC milling machine may be substantial, the long-term savings are evident. Reduced labor costs, minimized material waste, and faster production times contribute to a favorable return on investment (ROI).

2.5 Safe Operations

Modern CNC milling machines come equipped with various safety features that protect operators. Enclosed workspaces and automated operations reduce the likelihood of accidents, ensuring a safer work environment.

3. Applications of CNC Milling Machines

CNC milling machines have found applications across multiple sectors, showcasing their versatility and effectiveness:

3.1 Aerospace Industry

The aerospace sector demands unparalleled precision, and CNC milling machines deliver just that. Components produced for aircraft must withstand extreme conditions and be manufactured to exact specifications.

3.2 Automotive Industry

The automotive industry relies heavily on CNC machining for its component production. From engine parts to detailed interior components, the precision and reliability of CNC milling are unmatched.

3.3 Medical Sector

In medical manufacturing, the production of surgical instruments and implants requires a level of detail only achievable through CNC technology. The biocompatibility of materials used is critical, and CNC milling allows for high-quality finished products.

3.4 Consumer Products

CNC milling is also prominently featured in the production of various consumer goods, including electronics and household appliances. Its ability to produce complex shapes quickly has made it a standard in consumer product manufacturing.

3.5 Industrial Equipment

Manufacturers of industrial machinery utilize CNC milling to create parts that require high strength and durability. Gears, housings, and frames benefit from the robust capabilities of CNC machining.

4. Choosing the Right CNC Milling Machine

Selecting the right CNC milling machine for your business in the UK is critical for optimizing operations. Here are factors to consider:

4.1 Assess Your Needs

Evaluate the types of materials you will be working with and the complexity of the designs. Different machines cater to different needs, so assessing your requirements is essential.

4.2 Machine Size and Specifications

Choose a machine that fits your workspace and meets your production capacity. Consider aspects such as table size, spindle speed, and weight capacity.

4.3 Software Compatibility

Ensure that the CNC milling machine you choose is compatible with your existing CAD/CAM software. This integration is crucial for seamless operation.

4.4 Support and Maintenance

Opt for machines from manufacturers that offer robust support, including training and maintenance services. Establishing a relationship with a reliable supplier, such as roc-tech.com, can provide ongoing assistance and resources.

5. Investing in CNC Technology at Roc-Tech

At roc-tech.com, we pride ourselves on providing a comprehensive selection of CNC milling machines tailored to meet the diverse needs of businesses in the UK. Our offerings ensure that companies of all sizes can harness the power of CNC technology to drive growth and innovation.

5.1 Affordable CNC Machines for Sale

We offer competitive pricing on a wide range of CNC machines, making it easier for businesses to invest in cutting-edge technology without straining their budgets.

5.2 Expert Consultation

Our team of experts is ready to guide you through the selection process. We understand the nuances of your industry and offer tailored advice to ensure that you choose the right machine for your specific needs.

5.3 Training and Support

Purchasing a CNC machine is just the beginning. We provide extensive training and ongoing support to help your team maximize the potential of your new equipment.

6. Conclusion: The Path Forward with CNC Milling Machines

In conclusion, investing in a CNC milling machine in the UK is not merely a decision; it is a strategic move that can elevate your business to new heights. As we’ve explored, the benefits of precision, efficiency, and adaptability offered by CNC technology are unparalleled. With the support of trusted suppliers like roc-tech.com, businesses can embrace this technology confidently and pave the way for a future defined by innovation and success.

By choosing to invest in CNC milling machines, you are positioning your business to meet the challenges of tomorrow's manufacturing landscape. Step into the future of precision engineering today.

cnc milling machine uk